![]() Crosslinked sodium carboxymethylcellulose

Crosslinked sodium carboxymethylcellulose

Rating : 7

| Evaluation | N. Experts | Evaluation | N. Experts |

|---|---|---|---|

| 1 | 6 | ||

| 2 | 7 | ||

| 3 | 8 | ||

| 4 | 9 | ||

| 5 | 10 |

0 pts from Al222

| Sign up to vote this object, vote his reviews and to contribute to Tiiips.Evaluate | Where is this found? |

| "Descrizione" about Crosslinked sodium carboxymethylcellulose by Al222 (24031 pt) | 2025-Dec-13 20:01 |

| Read the full Tiiip | (Send your comment) |

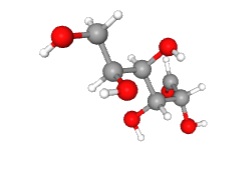

Crosslinked sodium carboxymethylcellulose

International designation: crosslinked sodium carboxymethylcellulose

What crosslinked sodium carboxymethylcellulose is

Crosslinked sodium carboxymethylcellulose is a hydrophilic anionic polymer derived from cellulose and chemically modified through carboxymethyl substitution followed by chemical crosslinking. The resulting three-dimensional network provides high water uptake, controlled swelling, and functional stability under use conditions.

It is commonly used as a rheology modifier, thickener, stabilizer, and (in specific grades) a superabsorbent functional polymer in cosmetic, pharmaceutical, and technical formulations.

Chemical identification and nomenclature

INCI / technical name: Sodium carboxymethylcellulose crosspolymer

Chemical name: Crosslinked sodium carboxymethylcellulose

CAS number: 9004-32-4 (carboxymethylcellulose family; crosslinked forms are typically treated within the same polymer family in technical documentation)

Chemical class: Modified cellulosic polymers

Functional class: Rheology modifier, stabilizer, absorbent polymer

Chemical structure and molecular description

The backbone consists of a cellulose polysaccharide chain (glucose-based repeating units). Carboxymethyl groups are introduced onto the cellulose hydroxyl sites, generally present as the sodium salt to enhance dispersion and ionic functionality. Crosslinking creates inter-chain bridges, yielding an insoluble but highly swellable polymer network.

This architecture underpins the material’s thickening performance, gel formation, and phase stabilization capabilities.

Meaning of the name and functional implications

Cellulose: Structural polymer backbone

Carboxymethyl-: Increases hydrophilicity and introduces anionic character

Sodium: Salt form that improves dispersion and ionic stability

Crosslinked: Network formation that prevents full dissolution and supports stable swelling

The name directly reflects the polymer’s structure–function relationship and explains its behavior as a swelling, viscosity-building network rather than a simple soluble polymer.

Raw materials and their functional role

Purified cellulose: Structural backbone and primary polymer matrix

Carboxymethylating agents: Introduce carboxymethyl functionality and ionic character

Crosslinking agents: Establish a three-dimensional network and control swelling

Sodium salts / neutralizing agents: Set the polymer in its sodium form and tune performance

Raw material selection and control strongly influence degree of substitution, crosslink density, and ultimately rheology and absorbency.

Industrial manufacturing process

Typical industrial production includes:

cellulose activation under controlled alkaline conditions

carboxymethylation (etherification) under controlled reaction parameters

a dedicated crosslinking stage to build the network structure

purification, neutralization, drying, and milling/classification

Tight control of degree of substitution and crosslinking level is essential for consistent viscosity, swelling, and stability.

Key physicochemical properties

Physical form: Fine powder

Appearance: White to off-white

Odor: Odorless

Solubility: Not fully soluble; strongly swellable in water

Rheological behavior: Gel formation; viscosity build depending on grade and shear

Stability: Generally good chemical and thermal stability under intended use conditions

Mechanism of action

Water uptake is driven by:

polymer–water interactions (hydrogen bonding)

ionic hydration around anionic sites

controlled expansion of the crosslinked network

The polymer forms a stable hydrated structure that increases viscosity, improves suspension stability, and can reduce phase separation and syneresis in appropriate systems.

Safety and general toxicological considerations

Crosslinked sodium carboxymethylcellulose is generally regarded as having a favorable safety profile for intended applications. It is typically considered low risk when used according to relevant technical specifications and good manufacturing/formulation practices.

In the food industry (1), it is a thickening and stabilising agent, and since the 1980s it has entered the oenological field (2).

Excessive intake of celluloses such as E465 may be associated with high risks of cardiovascular diseases (CVD).(3)

Regulatory status and compliance

Widely used across cosmetic, pharmaceutical, and technical applications

Commonly addressed within established frameworks for cellulosic polymers

Not generally classified as a hazardous substance under typical handling/use scenarios (grade- and jurisdiction-dependent)

Quality and production standards

Manufactured under controlled industrial standards

Key quality parameters typically include purity, moisture, particle size distribution, degree of substitution, and crosslink density

Performance consistency verified via viscosity/swelling and specification testing

Formulation compatibility and stability

Generally compatible with many hydrophilic formulation systems

Functional across a broad pH window (grade-dependent)

Performance can be affected by high ionic strength and strong electrolytes

Compatibility should be verified in systems containing high salt loads or strongly cationic components

Main applications

Cosmetics: Thickener, rheology modifier, stabilizer for gels and emulsions

Pharmaceuticals: Excipient roles such as disintegrant and functional matrix (depending on grade and design)

Technical/industrial: Absorbent and rheology modifier in aqueous systems

Environmental aspects

Being derived from cellulose (plant origin) supports a favorable raw-material profile. Crosslinking typically reduces immediate biodegradation compared to fully soluble cellulosics; however, these polymers are not generally associated with significant bioaccumulation under typical use patterns.

Technical notes

Performance is strongly governed by crosslink density and degree of substitution, which determine water uptake, gel strength, viscosity development, and processing behavior. Grade selection should be aligned with the target rheology profile, ionic environment, and processing shear.

References__________________________________________________________________________

(1) Regolamento (CE) N° 1333/2008 del 16 dicembre 2008 sugli additivi alimentari.

Determination of carboxyméthycellulose in food products - H.D Graham, Journal of food science 1971, p 1052-1055.

(2) Stabilisation tartrique des vins par la carboxyméthylcellulose - Bulletin de l’OIV 2001, vol 74, n°841-842, p151-159.

(3) Sellem L, Srour B, Javaux G, Chazelas E, Chassaing B, Viennois E, Debras C, Salamé C, Druesne-Pecollo N, Esseddik Y, de Edelenyi FS, Agaësse C, De Sa A, Lutchia R, Louveau E, Huybrechts I, Pierre F, Coumoul X, Fezeu LK, Julia C, Kesse-Guyot E, Allès B, Galan P, Hercberg S, Deschasaux-Tanguy M, Touvier M. Food additive emulsifiers and risk of cardiovascular disease in the NutriNet-Santé cohort: prospective cohort study. BMJ. 2023 Sep 6;382:e076058. doi: 10.1136/bmj-2023-076058. PMID: 37673430; PMCID: PMC10480690.

Sangalli ME, Giunchedi P, Colombo P, Conte U, Gazzaniga A, La Manna A. Cross-linked sodium carboxymethylcellulose as a carrier for dissolution rate improvement of drugs. Boll Chim Farm. 1989 Jul-Aug;128(7-8):242-7.

Abstract. The dissolution rate is often the limiting step in gastrointestinal absorption of water insoluble drugs from solid oral dosage forms. The aim of this work was to use a swellable polymer chosen among superdisintegrants, for improving the dissolution rate of a sparingly soluble drug, loaded on its surface. Nifedipine, which has a very low water solubility, was chosen as a model drug, while cross-linked sodium carboxymethylcellulose (Ac-Di-Sol) was chosen as the swellable polymer. The Nifedipine/Ac-Di-Sol systems were prepared using two different techniques: evaporation and spraying; in some preparations polyethylene glycol (PEG 1500), or sucrose palmitate (Sucrodet), or dioctyl sodium sulfosuccinate (Aerosol OT) were added. The results of the dissolution tests showed that the dissolution rate of Nifedipine from the systems prepared increases, particularly in the case of the preparation composed of Ac-Di-Sol plus surfactant agents.

DʼAloiso MC, Senzolo M, Azzena B. Efficacy and Safety of Cross-Linked Carboxymethylcellulose Filler for Rejuvenation of the Lower Face: A 6-Month Prospective Open-Label Study. Dermatol Surg. 2016 Feb;42(2):209-17. doi: 10.1097/DSS.0000000000000592.

Abstract. Background: Cross-linked carboxymethylcellulose (CMC) filler is a biosynthetic filler with very low antigenic risk. Objective: To assess the efficacy and safety of CMC filler in the rejuvenation of the lower face. Materials and methods: Two hundred eighty-seven procedures were performed in 174 patients: 115 nasolabial folds, 86 marionette lines, 29 bar codes, 14 cheek rhytides, and 43 lip rejuvenations. Results were evaluated at 3 (T1) and 6 months (T2) with photographic evaluation, Global Aesthetic Improvement Scale (GAIS), Modified Fitzpatrick Wrinkle Scale (MFWS) for nasolabial folds, Marionette Lines Grading Scale (MLGS), and Medicis Lip Fullness Scale (LFS). Results: GAIS was ≥2 in >91.05% of patients both in T1 and T2. MFWS score significantly improved at T1 (86.9% class ≤1, p < .001) and T2 (82.6% class ≤1, p < .001); in all patients in T1 and T2, median amelioration of MLGS was 2 ± 1 and there was a significant amelioration of at least 1 grade in LSF in both upper and lower lips. Conclusion: The use of CMC filler resulted in a significant and satisfactory amelioration of lower face aging signs with very low incidence of adverse events. Therefore, it should be considered a valid alternative to cross-linked hyaluronic acid fillers.

Leonardis M, Palange A, Dornelles RF, Hund F. Use of cross-linked carboxymethyl cellulose for soft-tissue augmentation: preliminary clinical studies. Clin Interv Aging. 2010 Nov 9;5:317-22. doi: 10.2147/CIA.S13813.

Abstract. Purpose: The continual search for new products for soft-tissue augmentation has in recent years led to the introduction of long lasting alternatives to hyaluronic acids and collagen that are composed of other polymers able to improve clinical persistence over time. This is the first report in which sodium carboxymethyl cellulose (CMC) has been chemically treated by the cross-linking process and thus used as a hydrogel for soft-tissue augmentation through injection with thin needles. The study evaluates, from a clinical point of view, the behavior of cross-linked carboxymethyl cellulose hydrogel used in the aesthetic field and its side effects so as to check the safety and performance of the polymer following intradermal injections. Patients and methods: This work shows the preliminary results of an ongoing clinical study conducted between 2006 and 2009, performed on 84 healthy volunteers (62 females, 22 males) aged between 18 and 72 years, for the treatment of 168 nasolabial folds, 45 perioral wrinkles, and 39 lip volume. Results: Study results show an excellent correction of facial defects. Tolerance and aesthetic quality of the correction obtained indicate considerable safety features and absence of side effects. From a clinical point of view, hydrogel is gradually absorbed into the injection site without migration issues. Conclusion: Cross-linked CMC hydrogel proves to be an ideal agent for soft tissue augmentation with regard to safety and ease of application. It did not cause infection, extrusion, migration, or adverse reactions in the patients who have been followed for two years. Delayed aesthetic results on facial wrinkles were very satisfactory.

Dellali M, Iurciuc Tincu CE, Savin CL, Spahis N, Djennad M, Popa M. Hydrogel Films Based on Chitosan and Oxidized Carboxymethylcellulose Optimized for the Controlled Release of Curcumin with Applications in Treating Dermatological Conditions. Molecules. 2021 Apr 10;26(8):2185. doi: 10.3390/molecules26082185.

| Sign up to vote this object, vote his reviews and to contribute to Tiiips.EvaluateClose | (0 comments) |

Read other Tiiips about this object in __Italiano (1)

Component type: Chemical Main substances:

Last update: 2025-12-13 18:46:24 | Chemical Risk: |