Sodium carboxymethyl cellulose (sodium CMC, sometimes also referred to as carmellose sodium) is a water-soluble, anionic cellulose ether obtained by partial substitution of the hydroxyl groups of cellulose with carboxymethyl groups in the form of their sodium salt. It appears as a white to off-white, odorless, free-flowing powder. Thanks to its thickening, stabilizing, binding, film-forming and suspending properties, it is widely used in pharmaceutical, cosmetic, food and technical/industrial formulations.

Chemical composition and structure

Sodium carboxymethyl cellulose is produced by chemical modification of natural cellulose, in which carboxymethyl groups are introduced along the polymer chain.

Backbone: β-1,4-D-glucose units forming a linear cellulose chain.

Substituents: carboxymethyl groups (–CH₂–COO⁻ Na⁺) attached to hydroxyl groups on the anhydroglucose units.

Degree of substitution (DS): typically in the range 0.4–1.4 per anhydroglucose unit; DS strongly affects solubility, viscosity and rheological behavior.

Molecular weight: can range from tens of thousands up to several million Daltons, depending on the grade and intended application.

Physical and chemical properties

Appearance: fine, hygroscopic, white to slightly yellowish powder.

Solubility: readily soluble in cold and hot water, forming clear to slightly opalescent colloidal solutions; insoluble in most organic solvents.

pH (1% aqueous solution): usually between 6.0 and 8.5, depending on grade and purity.

Viscosity: available in a wide range of viscosity grades (low, medium, high), controlled by molecular weight and DS; solutions typically exhibit pseudoplastic (shear-thinning) behavior.

Stability:

Other characteristics: forms flexible films, improves water retention, and can act as a protective colloid in dispersions and emulsions.

Production process

The industrial production of sodium carboxymethyl cellulose generally involves the following steps:

Alkalization of cellulose

Etherification (carboxymethylation)

The alkalized cellulose reacts with monochloroacetic acid or sodium monochloroacetate.

This step introduces the carboxymethyl groups along the cellulose backbone, forming sodium carboxymethyl cellulose.

Neutralization and purification

Drying and milling

The purified wet product is dried and milled to achieve the desired particle size and flow characteristics.

The process parameters (reaction time, temperature, reagent ratios) are carefully controlled to obtain consistent degree of substitution and viscosity grade.

Applications

Environmental and safety considerations

Sodium carboxymethyl cellulose is generally recognized as safe (GRAS) for its approved uses in food, pharmaceuticals and cosmetics when manufactured and used according to relevant regulations.

Toxicological profile: low acute toxicity; considered non-sensitizing and non-irritant in typical use concentrations for skin and mucosa.

Inhalation: like many fine powders, dust may cause mild, transient irritation of the respiratory tract; appropriate dust control and personal protective equipment are recommended in industrial handling.

Environmental fate:

Based on its cellulose origin, it is inherently biodegradable under suitable environmental conditions.

Does not bioaccumulate and is not considered environmentally persistent when released at normal levels.

Regulatory compliance: grades for food and pharmaceutical use must meet strict purity requirements (limits on salts, organic by-products, heavy metals and microbial contamination).

Conclusion

Sodium carboxymethyl cellulose is a versatile, cellulose-derived polymer widely valued for its thickening, stabilizing, suspending, binding and film-forming properties. Its tunable viscosity, broad compatibility with other excipients and ingredients, and favorable safety and environmental profile have made it a key functional ingredient across pharmaceutical, cosmetic, food and industrial sectors.

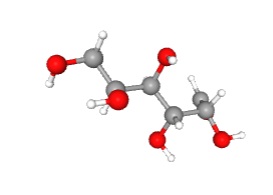

![]() Sodium carboxymethyl cellulose

Sodium carboxymethyl cellulose