Methyltrimethoxysilane is an organosilicon compound primarily used as a surface treatment agent and as a starting material in the production of silicone polymers. Due to its ability to form bonds with silicon, it is employed in a variety of industrial applications, including protective coatings, sealants, and as a component in cross-linking systems for polymers.

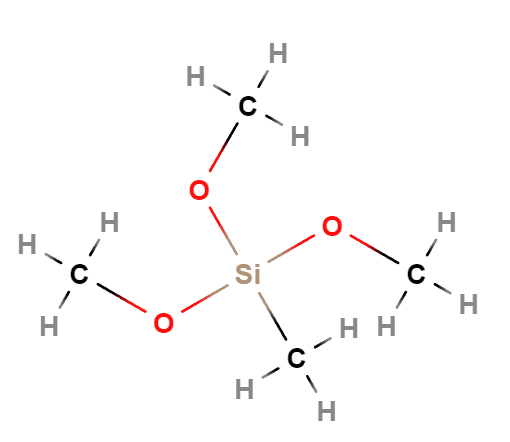

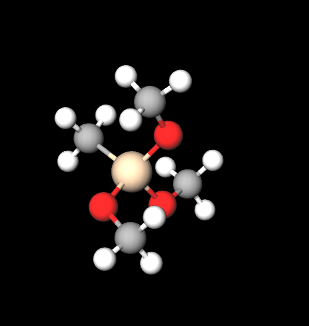

Composition. Methyltrimethoxysilane is a silane with three methoxy groups attached to a silicon atom, which can hydrolyze to form cross-linked siloxane structures.

Properties. This compound is known for its volatility and the ability to act as a hydrophobizing agent, increasing the water and moisture resistance of treated materials.

The name describes the structure of the molecule:

Methyl. This indicates the presence of the methyl group in the molecule. Methyl is a functional group composed of a carbon atom bonded to three hydrogen atoms (-CH₃).

trimethoxysilane. This indicates the presence of a trimethoxysilane group in the molecule.

Chemical Industrial Synthesis Process

The production of Methyltrimethoxysilane (MTMS), an organosilicon compound used as a silane coupling agent and starting material for the synthesis of silicone polymers, follows a chemical process that involves the reaction of methanol with silicon chloride under controlled conditions. Here is a detailed overview of the process.

- Basic Synthesis. Production begins with the reaction between silicon chloride (SiCl4) and methanol (CH3OH) to form Methyltrimethoxysilane. This reaction requires the use of a catalyst, typically a base, to facilitate the substitution of chloride groups with methoxy groups.

- Control of Reaction Conditions. The reaction is carried out under controlled temperature and pressure conditions to optimize the yield and purity of the product. Careful management of the reactant ratio and reaction time is crucial.

- Distillation. After the reaction, the reaction mixture contains Methyltrimethoxysilane along with by-products and reactant residues. Distillation is used to separate and purify Methyltrimethoxysilane from the other components of the mixture.

- Further Purification. Additional purification steps may be necessary to remove the last traces of impurities and achieve high-quality Methyltrimethoxysilane. These can include filtration, crystallization, or further distillations.

- Quality Control. The purified Methyltrimethoxysilane undergoes quality control checks to verify its purity, chemical composition, and physical properties. These tests can include spectroscopy, chromatography, and thermogravimetric analysis.

Form and Color. Methyltrimethoxysilane is a colorless to slightly yellow liquid.

What it is for and where

The function of this compound can vary depending on the context in which it is used. Methyltrimethoxysilane is often used as a binding agent or surface modifier in various industrial applications and materials such as resins and composites, where it can contribute to increased adhesion and corrosion resistance.

Applications. Used as a surface treatment agent, it promotes adhesion between organic and inorganic materials. It is employed in the production of silicones and as an intermediary in the synthesis of organosilicon compounds.

Benefits. Enhances thermal stability and water-repellent properties of the treated materials, also helping to improve adhesion between different substrates.

Cosmetics - INCI Functions

- Film-forming agent. It produces, upon application, a very thin continuous film with an optimal balance of cohesion, adhesion and stickiness on skin, hair or nails to counteract or limit damage from external phenomena such as chemicals, UV rays and pollution.

Molecular Formula C4H12O3Si

Molecular Weight

CAS 1185-55-3

UNII 0HI0D71MCI

EC Number 214-685-0

DTXSID3027370

Nikkaji J13.152K

Synonyms:

- Trimethoxymethylsilane

- Trimethoxy(methyl)silane

References_____________________________________________________________________

(1) Pellegrini C, Duluard S, Gressier M, Turq V, Ansart F, Menu MJ. Development of Multifunctional Hybrid Coatings (Mechanically Resistant and Hydrophobic) Using Methyltrimethoxysilane-Diethoxydimethylsilane-Tetraethoxysilane Mixed Systems. Materials (Basel). 2024 Jan 11;17(2):368. doi: 10.3390/ma17020368. PMID: 38255535; PMCID: PMC10817560.

Abstract. For many industrial applications, the simultaneous presence in a material of different functional properties is necessary. The main interest lies in making a single material more versatile and durable, less fragile and more efficient. In this study, two concomitant properties in the same material were mainly studied: resistance to cracking and the increase in its hydrophobic properties. The chosen process was the sol-gel route due to its versatility and the ease of formulating materials from various precursors in order to obtain (multi)functional materials. In this paper, sol-gel coatings were prepared with tetraethoxysilane, methyltrimethoxysilane and diethoxydimethylsilane as precursors. Tetraethoxysilane was mainly used to improve the material's mechanical properties, especially hardness, and silicon oil was added to improve its hydrophobic behavior. The integration of silicon oil was monitored via 29Si NMR. Microstructural characterizations were carried out to correlate the multi-scale properties with the microstructure of the derived films. Young's modulus and hardness were measured to highlight the effect of key formulation parameters on the mechanical strength of the coatings. The synergistic effect of these precursors is underlined as well as the beneficial effect of silicon oil (generated in situ or precondensed).

![]() Methyltrimethoxysilane

Methyltrimethoxysilane