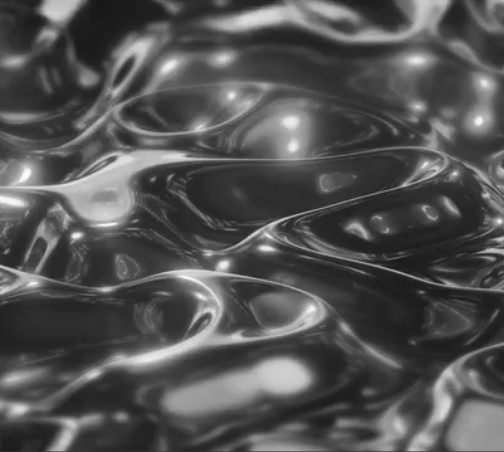

![]() Polycrystalline materials: deformability

Polycrystalline materials: deformability

Rating : 8

Polycrystalline materials: deformabilityIn a polycrystalline material with a face-centered cubic structure there are 12 sliding systems that allow for easy, low load motion of the dislocations. These materials are therefore easily deformable as a result of plastic processing (rolling, drawing, extrusion). Rolling involves the passage of a meta... (Read the full Tiiip)

16 pts from ivan

| Evaluate | Where is this found? |

| "Descrizione" about Polycrystalline materials: deformability Review Consensus 16 by ivan (999 pt) | 2021-Sep-18 16:56 |

Polycrystalline materials: deformabilityIn a polycrystalline material with a face-centered cubic structure there are 12 sliding systems that allow for easy, low load motion of the dislocations. These ...

| Read the full Tiiip | (Send your comment) |

Read other Tiiips about this object in __Italiano (1)

Component type: Natural Main substances: Last update: 2021-09-16 17:14:13 | Chemical Risk: |