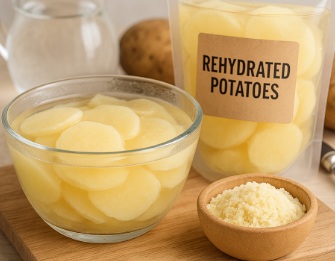

Rehydrated potatoes (reconstituted potatoes)

Description

Preparation obtained by rehydrating dehydrated potatoes (flakes or granules) with water and, depending on the application, milk, fats, or other auxiliaries. The result is a matrix of gelatinized starch with a texture ranging from purée to dough.

Dehydrated bases come from cooked, mashed potatoes drum-dried (flakes) or agglomerated (granules); they may include small amounts of emulsifiers (mono-/diglycerides), antioxidants/anti-browning agents (ascorbic acid), sequestrants (pyrophosphates) and occasionally sulfites (must be declared).

Caloric value (per 100 g)

Ready rehydrated potatoes (water only): ~70–95 kcal/100 g (depends on solids, typically 18–25%).

With milk/butter/oil, values rise in proportion to fat and added sugars.

Key constituents

Potato starch (mostly amylopectin with some amylose), largely gelatinized; on cooling it can form resistant starch (RS3) via retrogradation.

Water ~75–82%, protein ~1–2%, fiber ~1–2%.

Minerals: potassium relatively high; sodium variable (↑ if saline additives present).

Water-soluble vitamins are partly reduced by the cook–dry cycle; rehydration does not restore them.

Production process

Potatoes → washing, peeling, cutting → cooking/blanching → mashing and pre-seasoning → drying (drum-drying for flakes; fluidized-bed/extrusion–agglomeration for granules) → optional standardization with auxiliaries → barrier packaging.

Industrial rehydration: dose flakes/granules into hot water (and optional milk/fats) to target solids and viscosity; brief stand for full hydration.

Sensory and technological properties

Texture tunable via water/solids ratio and shear: from silky to more bodied; excessive shear yields gluey texture.

Acts as binder/texturizer: increases viscosity, improves water retention, reduces syneresis; promotes Maillard browning in baked/fried systems.

Stability: on chilling, retrogradation can thicken and cause weeping; manage pH, ions, and thermal profile.

Food uses

Mashed sides, gnocchi and potato doughs, croquettes/hash browns/tater tots, fillings and veg burgers, soups and sauces as thickener, bakery (breads, focaccia, extruded snacks) for softness and shelf-life.

Typical use levels: 4–8% flakes/granules of total weight in soups/sauces; 15–30% in doughs (gnocchi/croquettes)—pilot testing recommended.

Nutrition and health

Predominantly carbohydrate; fat negligible unless added.

Glycemic index (GI) tends to be medium–high when hot; retrogradation during cooling increases RS3 (resistant starch) and may attenuate glucose spikes.

Sodium depends on recipe/additives.

Sulfites: possible in some dehydrated bases; must be declared at ≥10 mg/kg (as SO₂).

Lipid profile

In water-only rehydrated bases, total fat is minimal. When adding fats, the lipid profile follows the chosen fat:

**MUFA** (monounsaturated fatty acids, e.g., olive oil): often neutral/favorable for blood lipids.

**PUFA** (polyunsaturated fatty acids, e.g., seed oils): potentially beneficial when balanced but more oxidation-prone.

**SFA** (saturated fatty acids, e.g., butter): excessive intake may raise LDL.

Quality and specifications (typical topics)

Dehydrated base: moisture ≤7–8%, very low aw, specified particle size/bulk density, no scorching/off-odors.

Rehydrated: target total solids and viscosity, stable pH, lump-free; microbiology compliant (pathogens absent/25 g).

Controls for sulfites (if present), metals, pesticides (raw potatoes) and additive declarations.

Storage and shelf-life

Dehydrated bases: cool, dry, barrier packs (against humidity/light); typical shelf-life 12–24 months.

Rehydrated product: ≤4 °C, use within 24–48 h; avoid repeated chill–reheat cycles.

Allergens and safety

Potato is gluten-free; check for possible traces from mixed facilities.

Sulfites (if present) must be labeled; consider sensitive individuals.

Managed under GMP/HACCP with CCP on post-rehydration time–temperature.

INCI functions in cosmetics

Not used as “rehydrated potatoes.” Related materials: Solanum Tuberosum (Potato) Starch/Extract (roles: absorbent, viscosity-increasing, skin conditioning).

Troubleshooting

Gluey texture: excessive shear or solids too high → reduce agitation, rebalance water/solids, add emulsified fats.

Lumps: incomplete hydration → “rain-in” dispersion into hot water, use low-speed whisks; pre-mix with milk/fats.

Cold syneresis: retrogradation → raise solids, add emulsifiers or a small share of modified starch, manage cooling profile.

Dull color/browning: over-heating or high pH → reduce time/temperature, use antioxidants/ascorbate.

Papery flavor: low-grade base → change supplier/grade; enrich with milk/oil or natural flavors.

Sustainability and supply chain

Valorization of peels (feed/biogas) and effluent treatment to **BOD/COD** targets; optimize energy/water in cooking and drying.

Prefer recyclable packaging; full traceability under **GMP/HACCP**.

Conclusion

Rehydrated potatoes provide versatility, convenience, and process consistency across savory and bakery applications. Mastery of hydration, shear, and formulation (solids, salt, fats) is key to optimal texture and stability.

Mini-glossary

**GI** — Glycemic index: relative glycemic response; higher when hot, can drop after cooling (↑ RS3).

RS3 — Resistant starch from retrogradation: less digestible fraction that may blunt glucose peaks.

**aw** — Water activity: “free” water; low aw improves microbial stability.

**GMP/HACCP** — Good Manufacturing Practice / Hazard Analysis and Critical Control Points: preventive hygiene systems with defined **CCP**.

**CCP** — Critical control point: process step critical to safety (e.g., post-rehydration time–temperature).

**SFA** — Saturated fatty acids: excess may raise LDL.

**MUFA** — Monounsaturated fatty acids: often neutral/favorable for blood lipids.

**PUFA** — Polyunsaturated fatty acids: beneficial when balanced; more oxidizable.

**BOD/COD** — Biochemical/Chemical oxygen demand: indicators of wastewater impact from processing.